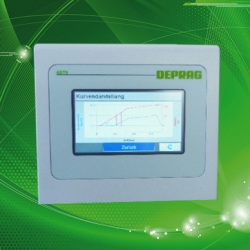

Besides the screwdriver itself, the screwdriving or sequence controller serves as an essential component of an electronic screwdriving system. Using the given parameters of the screwdriving program, the controller controls the EC-drive of the screwdriver, evaluates signals from sensors, and provides all necessary operator and documentation functions.

MINIMAT-EC and MINIMAT-EC Servo are key product lines within DEPRAG’s portfolio of screwdriving technology products, and both come equipped with highly dynamic brushless servo motors. However, they differ in the way the torque measurements are generated. While the EC-technology used with the sequence controllers AST5 and AST11 is based on the exact motor-current measurement, the EC Servo system with the available AST5-S and AST40 controllers evaluates the signal of the transducer integrated in the tool.

In addition to the applicable torque requirement, one more factor to be considered when choosing the most appropriate screwdriving system for the application at hand is the type of documentation or data output required. Moreover, selection of a suitable communication interface (for data exchange with the system environment) is also important.