Air motors are robust drive systems, used in areas where an overload-safe and powerful drive is needed, especially in areas where conventional drive technology might not be an option.

These motors operate according to one basic priciples: compressed air is used to set a rotor in motion inside an eccentric cylinder. Vanes, which are located in the rotor slots, are pressed outwards against the cylinder wall by the rising centrifugal force. This leads to the formation of chambers for the expanding air pressure. Through this expansion of the compressed supply air the pressure energy is transformed into kinetic energy and rotation is produced.

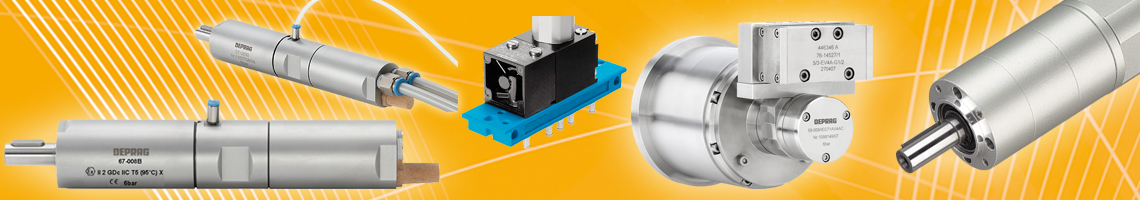

According to the individual application, air motors for the food industry need to be oil-free, sealed, and insensitive to the cleaning solvent. Medical motors need to be sterilizable, and pneumatic motors for specialized applications such as our drainage-milling robot and our ATEX compliant total systems; including air motor, brake, and gearing, are ready to be used in hazardous explosion environments. DEPRAG is able to supply air motors which meet all of the above requirements.

We are ready to help customers select the most economical and suitable drive solution for their particular application, whether this should be a standard air motor from our catalog program or a potentially more complex, customized system.

A resilient roto in the airmotor is the prerequisite for the long-time function of the motor. The rotors are mounted into a clamping fixture; they are fully turned, milled and the rotor gearing is manufactured. After the hardening, the manufactured rotors are given their final mesurement by highly exact polishers. The slots for the vanes are manufactured on the production machine, which was especially designed for DEPRAG and which guarantees the long life of the vanes.

With our standard cataloged air vane motors, we can offer adapted entirely drive solutions for your application.

Advantages:

Additional Product Information:

Turbines are efficient drives with extremely high-speed ranges. Starting with turbine and prototype manufacturing to mass production, our design team will support you!

Advantages:

DEPRAG turbines represent energy-efficient, high-speed drives capable of continuous operation, with a guarantee of low air consumption and an optimal power-to-weight ratio.

Application Examples:

Our gear motors offer a custom-designed solution for your application.

Advantages of this drive system:

Our gear motors offer a custom-designed solution for your individual application.

Learn more about our gear motors - Click Here