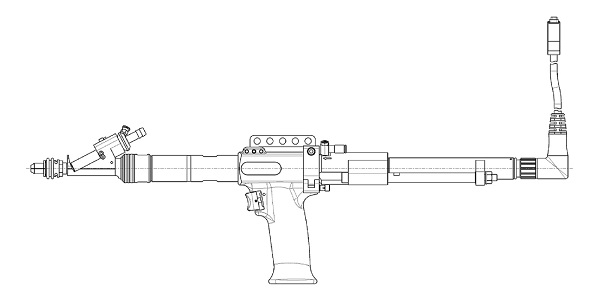

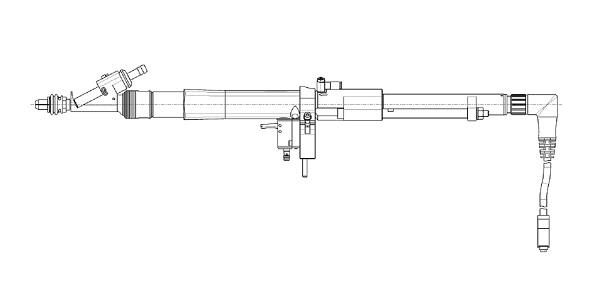

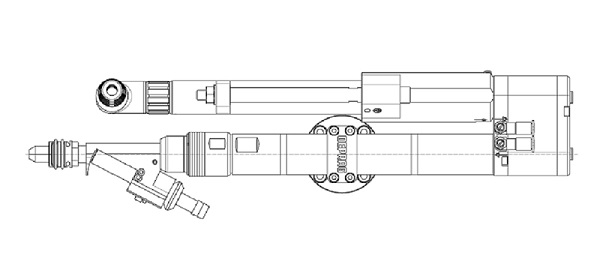

The DEPRAG Feed Module (DFM) combines an ergonomic handheld screwdriver with automatic screw feed to the Vibratory Bowl Feeder, Sword Feeder, or eacy Step Feeder.

Screws and nuts are positioned mechanically and secured by vacuum suction making it easier for the operator to access hard-to-reach screw positions. Integrated stroke mechanics use cylinders to precisely control the application pressure required for the fastener. This enables easier handling and fatigue-free assembly.

Benefits of the DEPRAG Feed Module in Manufacturing:

DFM manual screwdriver with automatic screw feed for fixtured and manual applications

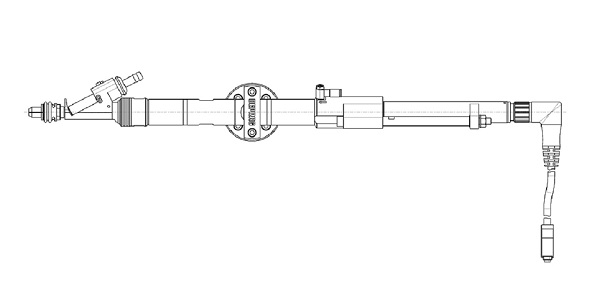

DFM is fully automated screwdriving with lightweight robots/cobots

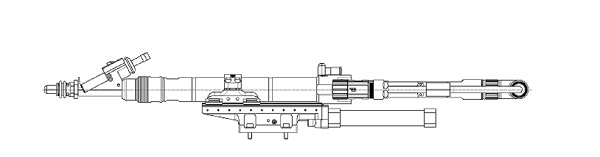

DFM Z-Stroke in place of Robot for fixtured use

DFM optimizes limited spaces

The versatility of the DFM is endless as it is suitable for manual, fixtured, and robotic screwdriving applications for both vertical and horizontal use.