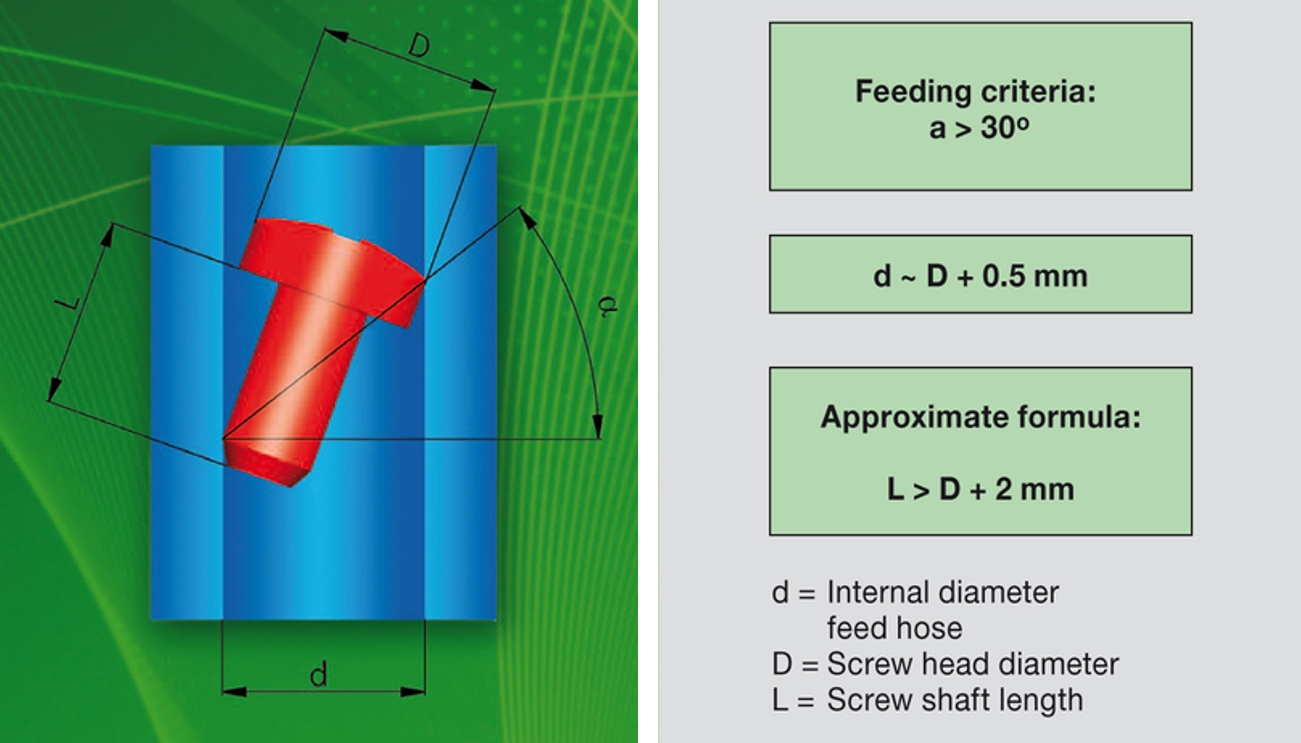

Screws with a very short shaft, rivets with a wide shaft-diameter and parts with complex external geometries have one thing in common: feeding through a feedhose is often not possible. Among feeding technology options, the pick-and-place method offers an alternative solution if the feedability criterion α is <30° (see diagram above).

Pick-and-Place Method

For handheld tools, the fastener is picked-up by vacuum suction or by a magnetic bit. The refill signal for the supply of the next component is generated by a pick-up control that is integrated into the cover. After removal of a component, the next component is automatically presented for pick-up.

For fixtured screwdriving applications, a vacuum pick-up technology or gripper-handling is used. The pick-up and reloading is controlled by PLC sensor supervision.

Standardized solution for parts up to max 14mm OD

Standardized solutions for parts up to max. 25 mm OD