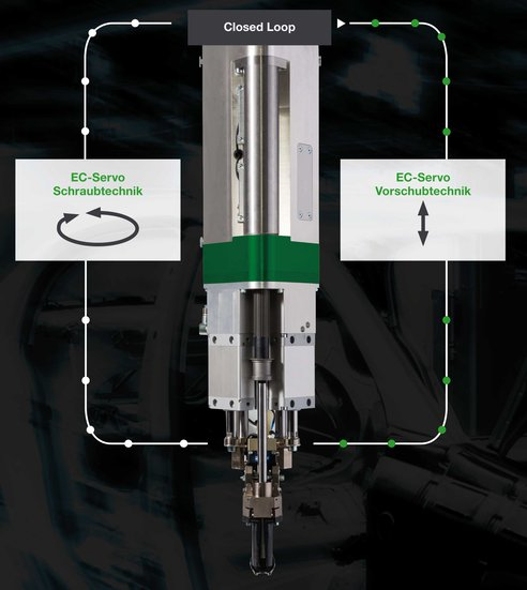

A formidable tool within DEPRAG’s screwdriving technology portfolio, the ADAPTIVE DFS combines EC-Servo screwdriving technology and EC-Servo stroke technology to drive both flow form and flow drill screws. This type of fastener technology has multiple uses and is frequently employed when lightweighting is the end goal – fasten steel to steel, steel to aluminum, or even sheet metal to carbon fiber!

The patented adaptive assembly unit ADAPTIVE DEPRAG FASTENING SYSTEM can prescribe and monitor the feed speed and feeding procedure. The constant flow of data reported by the control modules enable the precise and automatic recognition of all relevant penetration points. The fastening system autonomously performs time-critical and essential parameter changes.

The fastening system autonomously performs time-critical and essential parameter changes. Moreover, it ensures the ideal processing parameters, independent of the product tolerances or the fastener. It significantly reduces the effort of preliminary analysis and characterization. Costly and extensive repair procedures - caused by imprecisely formed holes, jammed screws, or ruined threads - are minimized.

The process parameters are automatically optimized to guarantee that the parts to be joined (fastener and product). Extensive real-time processing and equipment data are logged for each joint. DEPRAG's software tools allow for a simple analysis of the results and trends.

Separate electronic regulation of the EC-Servo screwdriver and the EC-Servo stroke technology, combined with the extensive parameterization possibilities, ensure the highest flexibility when processing various materials and material combinations.

The implementation of unique tightening sequences for new fasteners and materials is possible. The controlled feed stroke allows exact positioning and transition-points to be clearly defined, especially for the assembly of more modern materials such as carbon-fiber (CFRP).